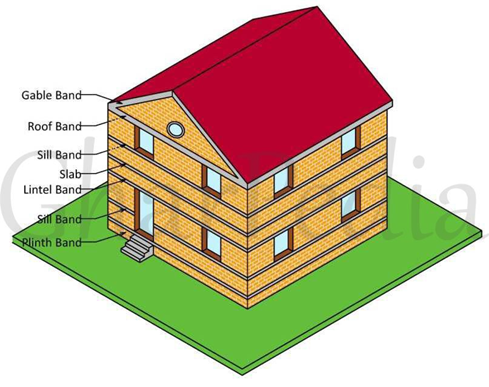

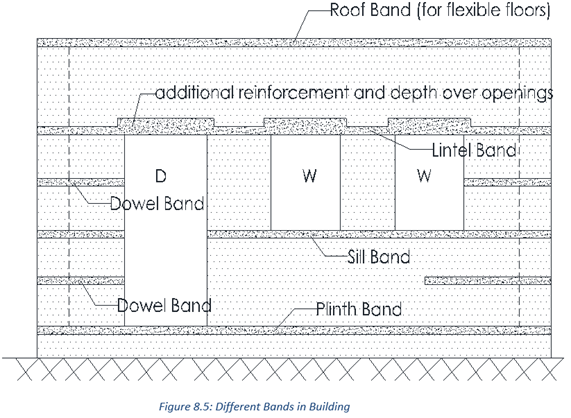

Different types of bands used in the masonry wall

- Plinth Band – provided at plinth level

- Sill Band – provided at sill level

- Lintel Band – provided at lintel level

- Slab – provided at floor level

- Roof Band – provided at roof level

- Gable Band – Provided on gable

- Stitches – Provided at corners

For more details: https://gharpedia.com/blog/importance-of-rcc-bands-in-load-bearing-structure-masonry-building/

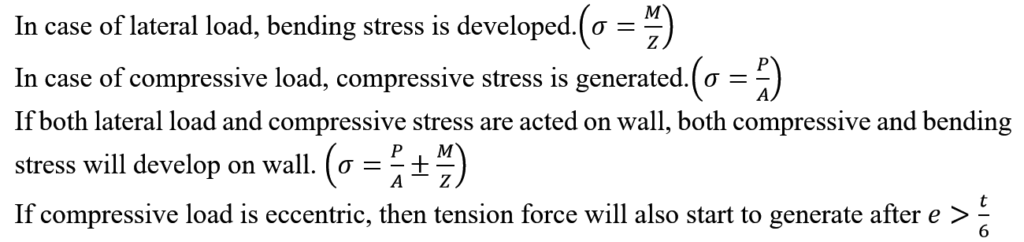

Failure behavior of masonry wall in lateral load and compressive load.

Lateral Load – In plane failure and out of plane failure

Compressive Load – Crushing failure of masonry

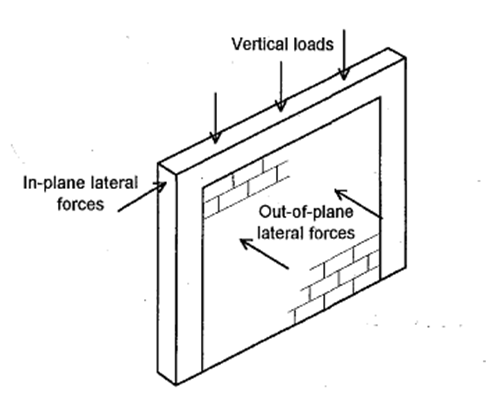

In plane and Out of plane failure of Masonry Structure

In plane failure – Lateral Load acting along the plane of masonry wall.

Out of plane failure – Lateral Load acting perpendicular to the plane of masonry wall.

Obviously, out of plane failure is dangerous.

Walls are relatively flexible in out-of-plane bending and offers relatively lower moment of resistance.

Remedies

- Provide Bands at different levels (Plinth, Stitches, Sill, Lintel, Gable)

- Construct Cross wall and buttress wall at suitable interval.

Wall need to be anchored to cross-walls properly by using dowels that will protect them against excessive out-of-plane bending.

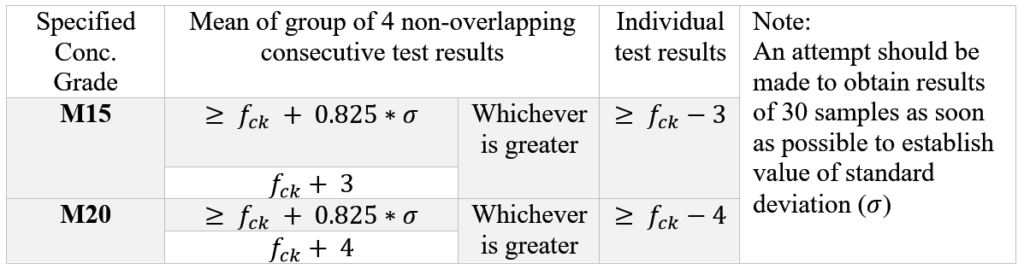

Information required for Concrete Mix Design

- Grade Designation (Required Grade of Concrete)

- Types of Work (RCC, PCC)

- Maximum Nominal Size of Aggregate

- Shape of Coarse Aggregate

- Workability

- Slump

- Compaction Factor (C.F.)

- Fine Aggregate confirming grading zone

- Exposure Condition

- Type of Cement

- Grade of Cement

- Specific Gravity of Cement, Coarse Aggregate, Fine Aggregate

- Free moisture content of fine aggregate and coarse aggregate

- Water Absorption for fine aggregate and coarse aggregate

- Fineness Modulus of Fine Aggregate and coarse aggregate

- Dose of Admixture

- Reduction in water content due to admixture

If you need excel sheet of concrete mix design, you can email me.

Methods of Curing

- Water Curing

- Immersion – Precast

- Ponding – slabs, pavements

- Sprayings – plasters, vertical concrete

- Wet-covering (saw-dust, sand, jute, etc) – vertical surface, concrete in difficult position

- Membrane Curing

- Concrete covered with thin membrane to prevent evaporation loss.Generally used after 2-3 days of water-curingUseful in inaccessible areasA thin impervious layer is created on the surface of the concrete.

- Example Bitumen, polyethylene, water-proof paper, rubber compounds, etc.

- Application of Heat

- Steam curing gives uniform temperature – no differential expansion crack

- Fast method, and useful in congested area.

- Useful in pre-cast industry

- Heat increases the rate of hydration as-well.

- Miscellaneous

- Chemicals like calcium chloride are used as surface coating. It absorbs moisture from atmosphere as stays wet for longer period.

Quality control of concreting in cold temperature

- Shielding of wind in the working area and insulating the plant with insulators.

- The site shall be well managed for quick delivery, finishing and covering of the concrete with insulator like straw, jute sacks, plastic sheets, water-proof paper, etc.

- The material for concrete can be pre-heated. Water can be easily heated in a container. Coarse aggregate can be heated with closed steam coils under stock pile, or by steam or hot air, if stored in a room. Sand can be heated over steel plates, while cement shall not be heated.

- The form-work or sub-grade can also be heated (to the temperature of concrete) so that heat of concrete is not absorbed by them.

- Special type of cement like rapid hardening cement, high alumina cement, etc. can be used that have higher heat of hydration and keeps the concrete warm.

- Accelerating admixtures is also commonly used that increases the rate of hydration. Calcium chloride is a good accelerator, but use in higher amount increases the corrosion in steels embedded in RCC.

- Where possible, electrical heating can also be adopted for curing (maintaining the temperature) of the concrete by passing alternating current through it.

- Where caging is possible, especially in pre-cast industry, low pressure steam (or hot air) circulation maintains the temperature thus accelerating the hydration

Quality control of concreting in hot temperature

- Management of Materials

- Aggregates shall be stock-piled in shade.

- Regular sprinkling of water to aggregate.

- Arrangement for circulation of cold air in aggregates.

- Using cold water (up to 5oC)

- Low heat cement can be used.

- Retarding admixtures are also helpful in delaying the setting process.

- Management of Concreting Work:

- Scheduling the concreting work in evening (but with sufficient lighting)

- Use of more masons for quickly finishing the work.

- Transporting the concrete in deep containers.

- Covering of concrete with moist materials as early as possible.

- Curing of Concrete:

- The concrete shall be cured with cold water.

- The surface shall be continuously made wet either by ponding, or using water absorbing materials in surface like cloth, jute, sand, etc.

- If possible, shade shall be maintained on the concrete.

If the Cube test fails, as a technical supervisor what do you do on that critical situation?

Check Acceptance Criteria

- If 28th days concrete cube test results fail checks if the result of all 7 days’ cubes is the same. If even one passes the acceptable criteria you are sure that the concrete mix is OK.

- Even if one of the cubes is OK wait for a 28 Day result.

- If 28 days’ result fails, then again there is a possibility that cubes are not filled properly or they were not cured properly in the first 7 days. But it is possible that slab concrete is OK. Go for the Hammer test.

- If the hammer test is also as per failed cube result then go for core cutter and test it to get actual strength of laid concrete.

- There are many options to strengthen a weak concrete member if concrete cube fails in test (Strengthening Techniques)

For more details: https://civiconcepts.com/blog/what-next-if-concrete-cube-fails-in-test

During the concreting, if the slump test fails, what do you do as a technical supervisor?

- If the on-site slump test fails, the site engineer may use his/her contractual power and reject the concrete and suspend the concreting process.

- However, it is believed that a slump test is just a measure of concrete consistency, and it may not cause the reduction of concrete strength. So, the site engineer can allow the contractor to continue concreting work, but proper slump adjustments should be made.

- If the concreting process is permitted to be finished, the contractor still needs to prove that the finished work complies with other contractual requirements, such as a compression test.

- Engineers should be aware that the workability is related to both strength and durability of concrete. If the concrete attains the designated strength, the durability may still get affected.

- If the concrete slump value is too high, the site engineer may allow the mixer to revolve for 8 to 10 minutes to reduce the slump. If the test still fails, one may add cement to the concrete mix to minimize slump value.

For more details: https://theconstructor.org/concrete/site-slump-test-fails/176167/